The design and construction of tools and automations to produce many different parts is one of our main activities since the earliest years. Thanks to the multidisciplinary contribution guaranteed by resources with solid and updated skills, in Sacel Group we continue to test, improve and perfect every aspect.

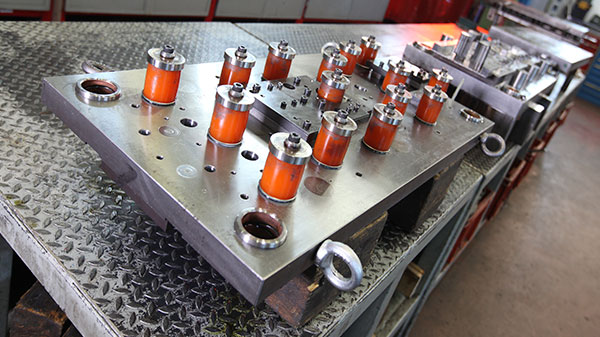

Design and construction of progressive dies

Our R&D department offers each single customer support and personalized solutions, developing together with the customer company the engineering of the product. The co-design activity is dedicated to strictly maintaining the customer’s requirements unchanged and to creating each part with the progressive stamping process alone.

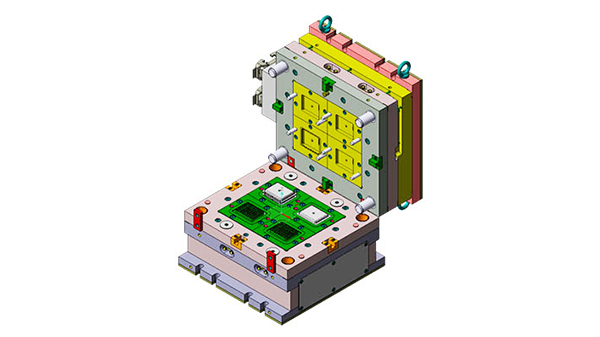

Design and construction of plastic injection dies

For this technology too the work of our R&D department is fundamental. It verifies and elaborates the best solution for each customer, from design study to the engineering and realization of the product. Customer’s requirements are always the starting point for reaching the target and obtaining the desired part through the thermoplastic injection process.

Design and construction of automations

For complex processes our R&D department is able to propose completely automated solutions, designed and produced by us, which can also include the control and packaging phases of the part, guaranteed 100% in terms of quality. Furthermore, the possibility to integrate the two main Sacel Group processes in the automated manufacturing enables us to obtain parts without any handling between the production phases.

Method and multidisciplinarity

The added value that Sacel Group can guarantee to each customer is the complete management of each phase of the project. Managers, engineers and specialized workmen work with versatility and according to rigorously tested methods, a multidisciplinary approach and continuous skills updating in order to ensure excellence and quality at each step: from the first CAD drawing to the After Sales.